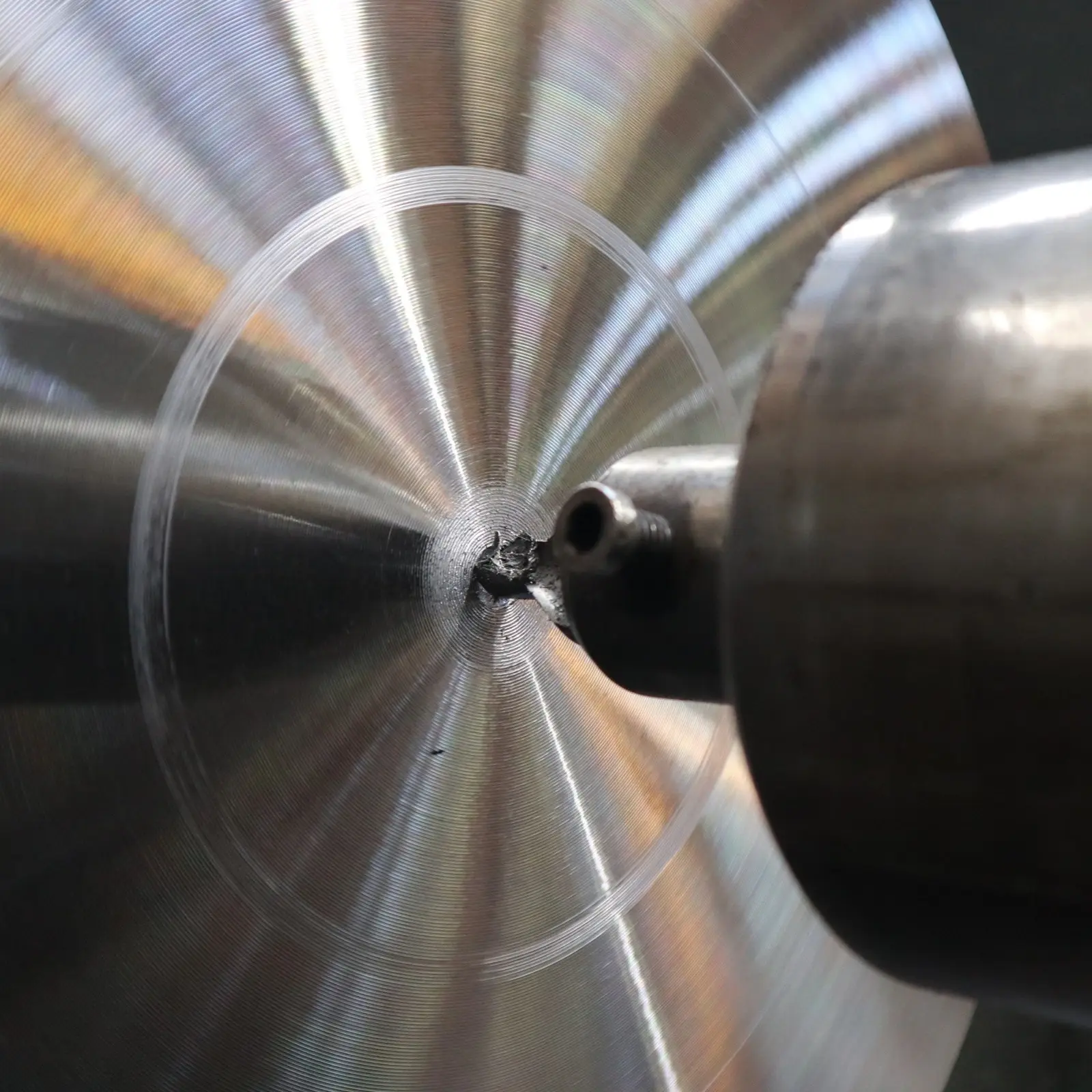

Various centering devices enable us to center cut sections on one or both sides. This means you can load the raw material you purchase from us directly onto your machine without wasting valuable time!

- DIN 332 Form D – centering with core thread M5-M36

- DIN 332 Form B – centering in all standard sizes without thread

- With or without protective countersink